|

Honor Inspection International Ltd.

|

QC-inspection in the Asia

| Price: | 208.0~250.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

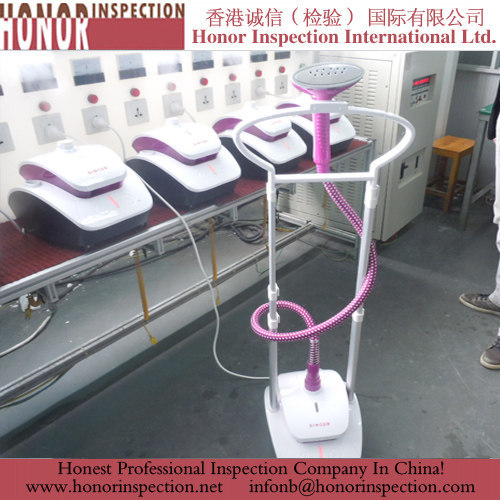

Because is the new product, with each component is not perfect, especially pay attention to the function, assembly, appearance...

Because is the new product, with each component is not perfect, especially pay attention to the function, assembly, appearance...

QC-inspection in the Asia

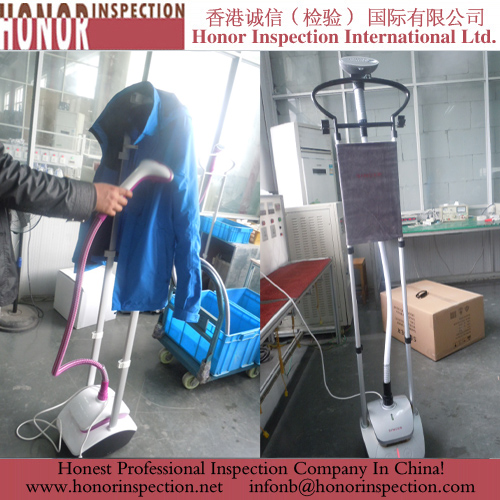

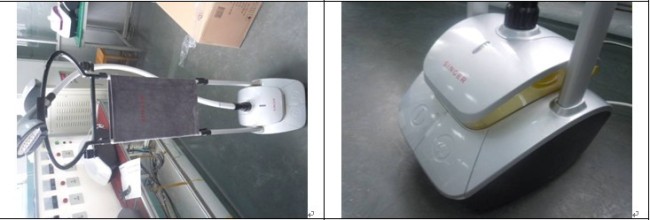

According to the specification, all the accessories are assembled, mark the defective position, especially the assembly problem.

QC-inspection in the Asia

Sealing test of accessories,This is absolutely not allowed water leakage and seepage poor sealing problems.

QC-inspection in the Asia

Found that poor assembly, switching function abnormal...

QC-inspection in the Asia

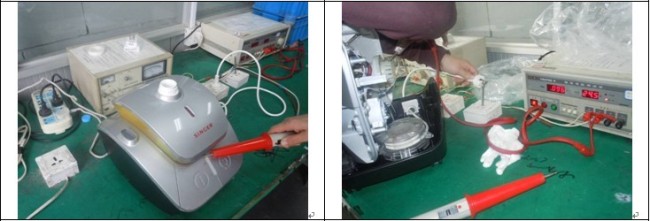

Electric Safety Test:HI-POT test,Earthing continuity test,Flashover or breakdown occur.

QC-inspection in the Asia

If you have a test problems, please contact me, be happy for you.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Inspection Service

Quality Inspection

Inspection Machine

Inspection System

Fabric Inspection

Inspection Mirror

More>>