|

Honor Inspection International Ltd.

|

quality control in china

| Price: | 208.0~250.0 USD |

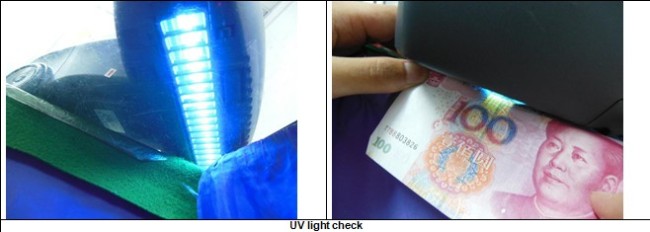

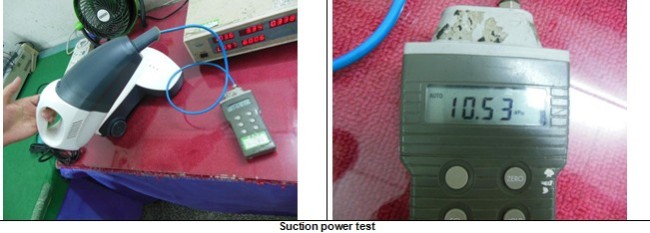

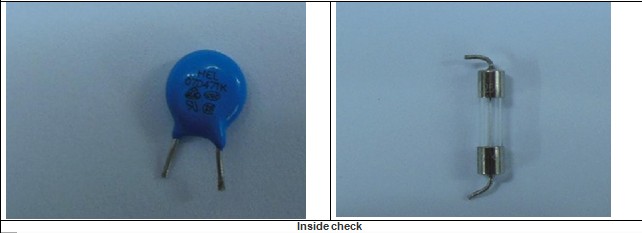

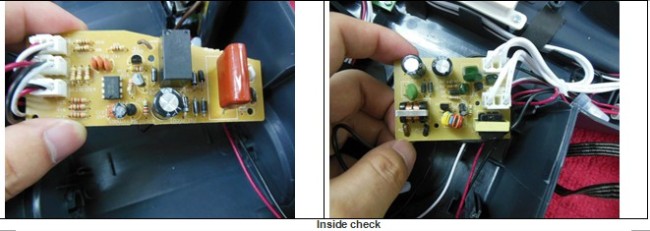

| Payment Terms: | T/T |

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

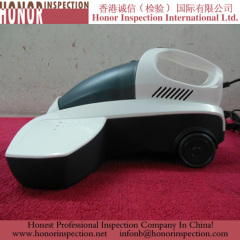

What are the common defects of Vacuum Cleaner and what does it may cause?

1. Suction weakened, which maybe caused by stainless steel telescopic tube

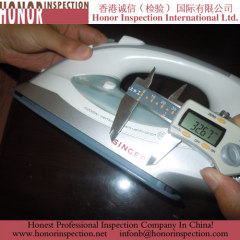

Inspection Item: Vacuum Cleaner Inspection in China

The whole inspection contains 6 major categories. Random Sampling, Audit the printed information, Appearance, Accessories, Test, Function test, Parts. (More details are in the actual report)

1. Random Sampling, select certain quantity of products to make the inspection and by using scientifical methods to judge the defects of all the products.

2. Audit the printed information, it is the basic of doing other inspections and make sure the printed information are met client requirements.

3. Appearance, Carefully check the appearance to make sure that the product will not influence the sell in market, normal defects like dirty mark, scratches are always reduce customer's interst in the product, if possible, we hope the appearance can give potential customers with visual pleasure and promote the sell.

4. Accessories, it is set to ensure that no accessories are missed, clients' requirements are met and not influence the function.

5. Check the basic functions to make sure the products will not go wrong in a easy way. Most of the products got defects in this process, and the defects may cause danger for user.

6. Function test, it's the major content of the whole inspection, on neglect can be accepted. Above are just part of the whole inspection.(More details are in the actual report)

What are the common defects of Vacuum Cleaner and what does it may cause?

1. Suction weakened, which maybe caused by stainless steel telescopic tube and hose is blocked, too much garbage in the dust cup, or too much dust on the filter.

2. Strange sound can be heard when the motor is working. It may be a result of stainless steel telescopic tube and hose being blocked.

Honor inspection is ready to help you find them, please contact us if you are worrying about them.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Quality Control

Quality Control Service

Quality Control Inspection

Bone China

Bone China Cup

Bone China Mug

More>>