|

Honor Inspection International Ltd.

|

Gold Index: 23225

Product (263)

- Factory Audit (5)

- In Process Inspection (9)

- Pre Shipment Inspection (34)

- Container Loading Inspection (8)

- Initial Production Inspection (2)

- Production Monitoring (1)

- Laboratory Testing (5)

- Iran VOC(COI) Inspection Services (2)

-

Products Inspection Display

(117)

- Hardware inspection (35)

- Gift Inspection (3)

- Stationery Inspection (5)

- Electric product inspection (48)

- Furniture inspection (10)

- Textile inspection (16)

- Inspection Services In China (6)

- Inspection Services In Asia (11)

- Quality Control Services (43)

- Inspection Services Company (20)

News (29)

FAQ (5)

Overseas Client (4)

Inland Client (7)

Why choose us ! (1)

Our Price (1)

Order Inspection (1)

Credit Report

Products Index

FAQ

How does sampling work during an inspection?

How does sampling work during an inspection?

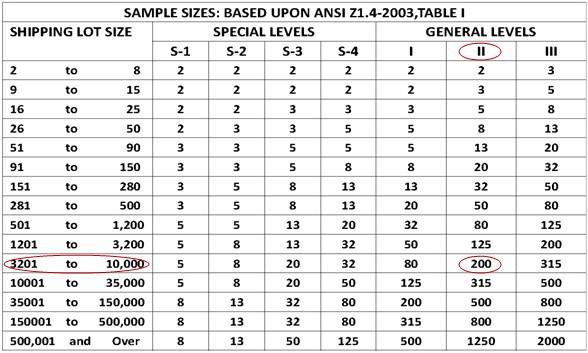

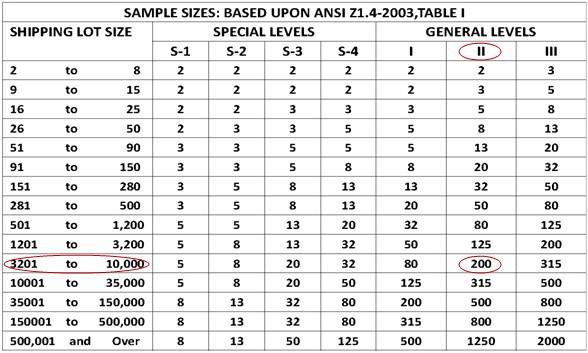

Honor Inspection recommends ANSI Z1.4 2003 sampling tables to determine the number of units that will be randomly selected for evaluation. Single and double normal sampling plans are the most commonly used.

If you do not set sampling requirements, Honor Inspection will assist you in determining which plan works best for your specific needs.

Samples are checked against a detailed inspection plan for appearance, applicable functionality, package integrity, workmanship, etc.

Defects are classified as major, minor, or critical, depending on inspection plans. The acceptable quality level (AQL) is determined by totaling the defects and using the corresponding accept/reject criteria within the sampling plan.

Pre Page:

How the reports are provided?

.gif)